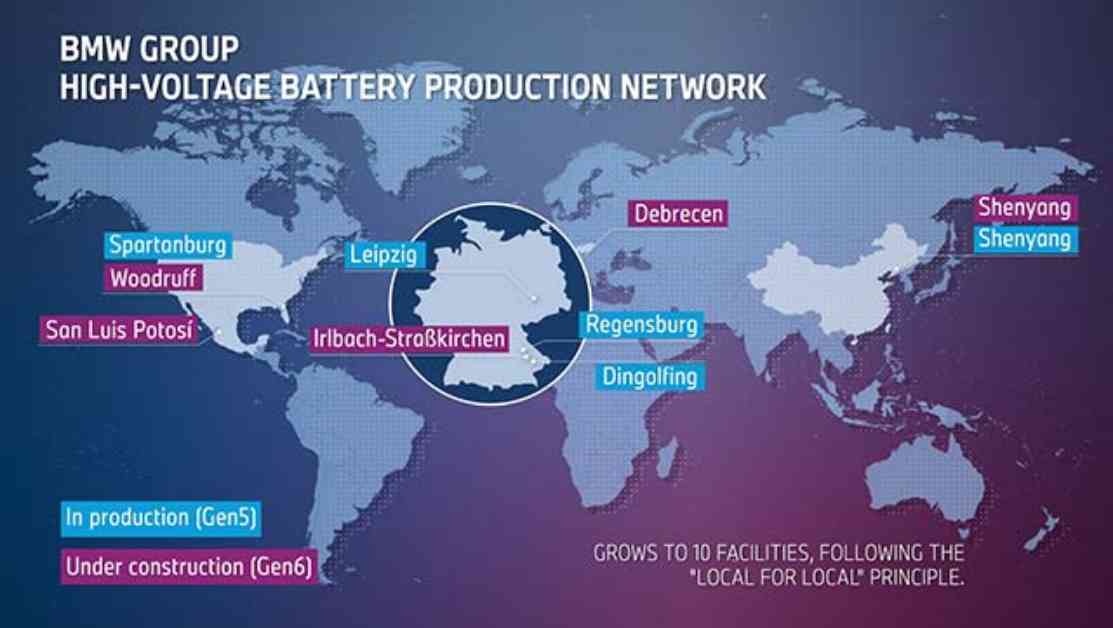

The BMW Group is gearing up for a new era of fully electric driving with the introduction of the Neue Klasse, which will heavily rely on the production of powerful high-voltage batteries. To support this initiative, the BMW Group is expanding its production network by establishing five new facilities on three different continents to produce the sixth-generation high-voltage batteries.

According to Milan Nedeljkovi?, Board Member for Production at BMW AG, the company is implementing a “local for local” approach, ensuring that battery production is closely connected to vehicle production. This strategy aims to enhance production resilience and reduce the carbon footprint of car manufacturing. The new high-voltage batteries will feature advanced cylindrical cells, offering improved energy density, charging times, and range.

State-of-the-art assembly plants for the sixth-generation high-voltage batteries are currently under construction in various locations, including Irlbach-Strasskirchen in Lower Bavaria, Debrecen in Hungary, Woodruff near Plant Spartanburg in the US, Shenyang in China, and San Luis Potosí in Mexico. These facilities will play a crucial role in ensuring the seamless production of the Neue Klasse vehicles.

The first Neue Klasse vehicles are expected to be produced at the BMW Group’s new plant in Debrecen starting in 2025. Both high-voltage battery and vehicle manufacturing will kick off simultaneously. The company has already opened a training center in Debrecen and is actively preparing its employees for the upcoming series launch in the second half of 2025.

In addition to Debrecen, China will also play a significant role in producing the Neue Klasse vehicles, starting from 2026. BMW Brilliance Automotive (BBA) in Shenyang will manufacture the cars locally, along with the required sixth-generation high-voltage batteries. The construction of the production hall in Shenyang is already underway, with the first pre-series batteries expected to be produced later this year.

Furthermore, production capacity is being expanded in San Luis Potosí, Mexico, to commence series production of the Neue Klasse in 2027. The BMW Group is also investing in enhancing its existing facilities, such as expanding the bodyshop and vehicle assembly spaces at Plant San Luis Potosí.

Electromobility is making strides in South Carolina as well, with BMW Group Plant Woodruff set to assemble high-voltage batteries for fully electric cars produced at nearby Plant Spartanburg. The completion of the Woodruff facility in 2026 will create over 300 new jobs with the BMW Group, further contributing to the growth of electromobility in the region.

Moreover, the BMW Group is establishing a new high-voltage battery assembly plant in Irlbach-Straßkirchen, Lower Bavaria, to supply sixth-generation high-voltage batteries to German car plants. The citizens of Straßkirchen have shown overwhelming support for the project, paving the way for the construction of the new facility.

In conclusion, the BMW Group’s commitment to producing high-voltage batteries locally and integrating them closely with vehicle production underscores its dedication to advancing electromobility and sustainability in the automotive industry. The company’s strategic expansion of production facilities across different continents signifies a significant step towards a greener and more efficient future of mobility.